Build Sequence - The 24 Hour Kayak

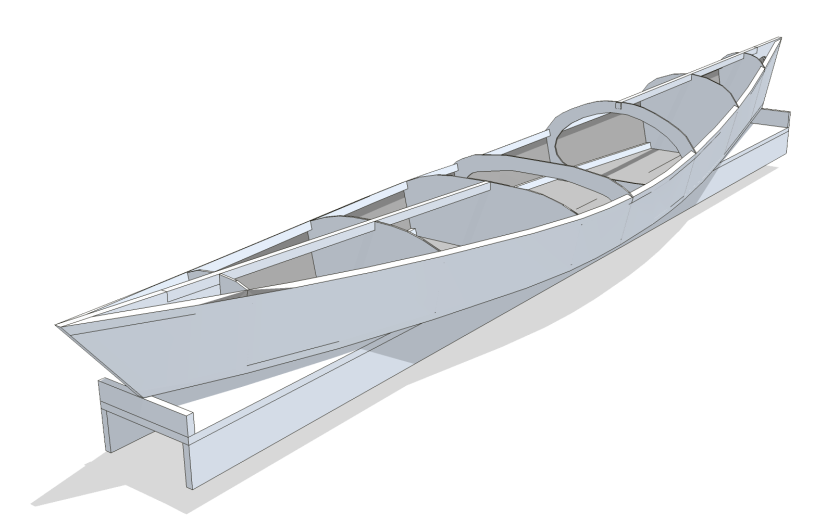

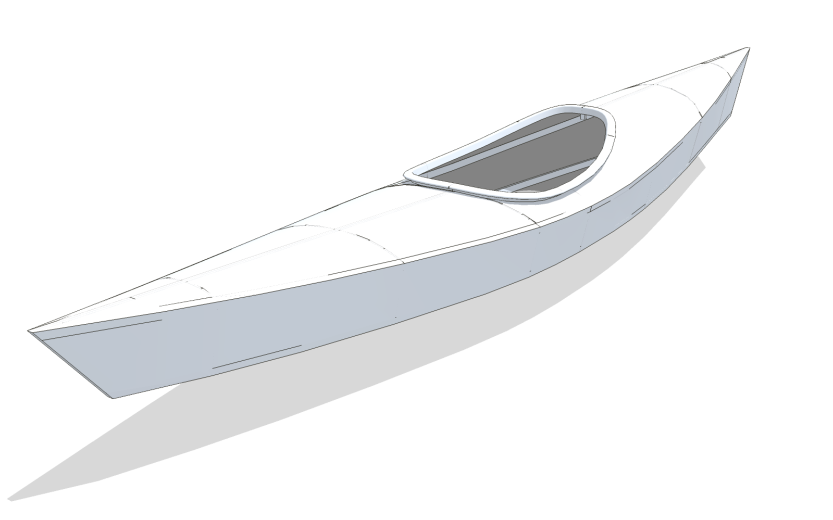

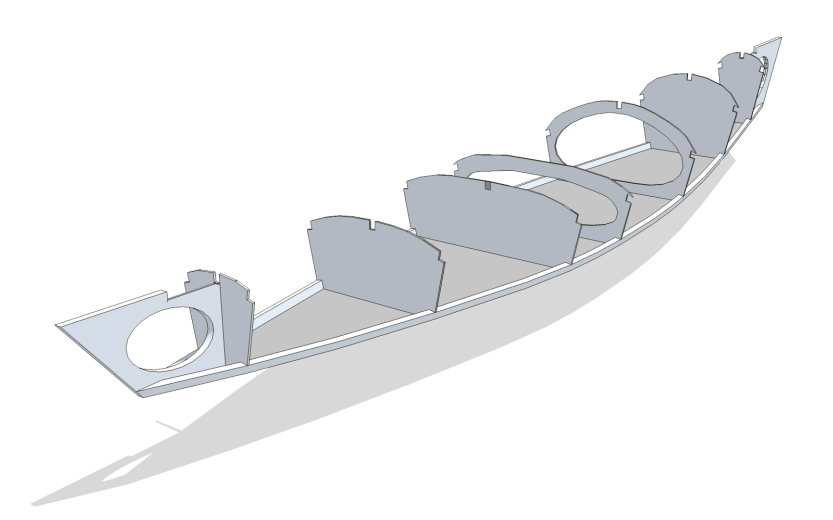

The drawings on this page provide builders with an overview of how the 24 Hour Kayak is assembled.

Note: This page is in place for those currently building prototype versions of the 24 Hour Kayak. Final plans and instructional materials will be published in late Spring, 2019. If you’d like to know when the plans are officially released, subscribe to Ashes Newsletter or our Facebook page, where the announcements will be made.

![]()

SUBSCRIBE

Step by Step Assembly Sequence

These drawings refer to the frame and panel assembly sequences. Builders should consult the hour by hour instruction modules for specific cutting and assembly instructions.

(Please note: the hour by hour instructions will be published at the same time as the plans, sometime in late spring 2019)

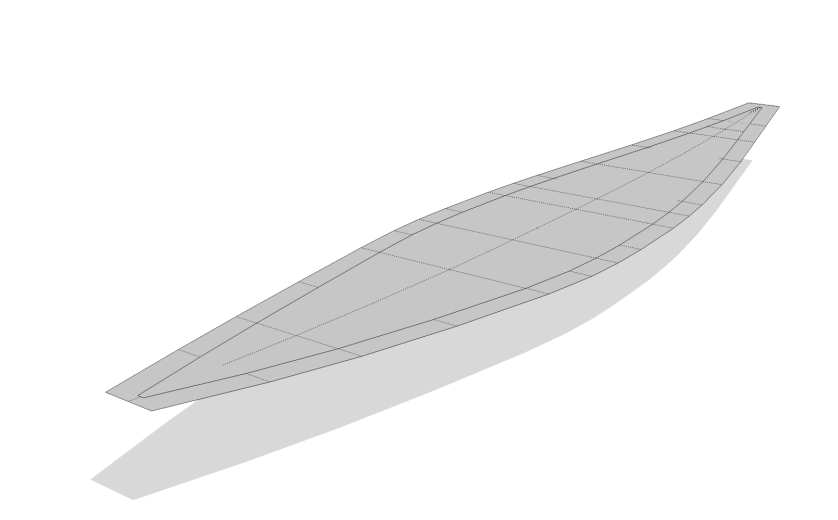

Laying Out the Bottom Panel

Panels are cut to their final dimensions only AFTER they’ve been attached to the basic frame (chine-logs and stations). As such, builders will initially cut the bottom panel outside the final lines. In this image the solid inside line represents the eventual trimmed dimension. Refer to the your measured drawings for proper dimensions.

Temporarily Placing the Stems

The stems are temporarily tacked in place so that the bottom chine-logs have a landing place. The stems will be removed shortly so don’t glue them in place yet!

Fitting the Bottom Chine-Logs

Now is the time to fit the bottom chine-logs. Use a back-saw to trim the chine-logs flush with the stems. Novices may wish to make some practice cuts to ensure that the angles are correct. You will also want to attach with a waterproof construction adhesive. If you’re of the sloppy sort, use painters tape to keep things clean and tidy up after with mineral spirits or paint thinner.

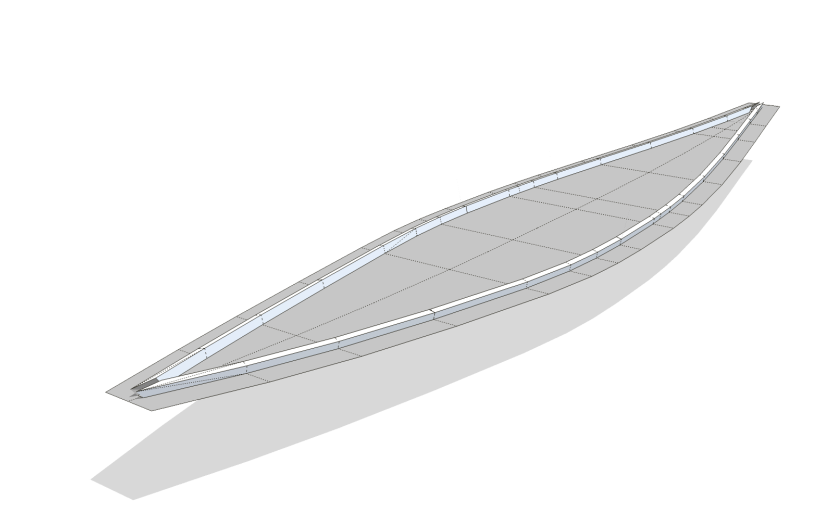

Trimming the Bottom Panel

The stems are removed and the bottom panel is trimmed using the chine-logs as guides.

A laminate trimmer run along the top of the chine will make a nice clean cut, but be CAREFUL. Know what you are doing and practice in advance if you haven’t used a trimmer before. Its also possible to trim close to the lines with a jigsaw, after which the panel can be cleaned up with a plane of belt sander.

These drawings show the panel before and after trimming.

Permanently Attaching the Stems and Stations

Once the bottom panel is trimmed, stations and stems are glued and screwed to the bottom panel AND to the chine log. Remember though, the two centre stations are temporary so those are NOT glued and care needs to be taken that screws won’t be buried later!

Attaching the Frame to the Strongback

The frame is firmly screwed to the strongback at mid-ships at the centre of bouancy (refer to your plans), with blocks under the nose and tail. Now is the time to ensure that the boat is square and without twist.

The front block is set at 3″ and the aft block is set at 2″. This sets in the rocker and is critical to the shape and function of your kayak.

Attaching the King Planks

The king planks are installed next; they will lock frames into place and provide support for the deck panels

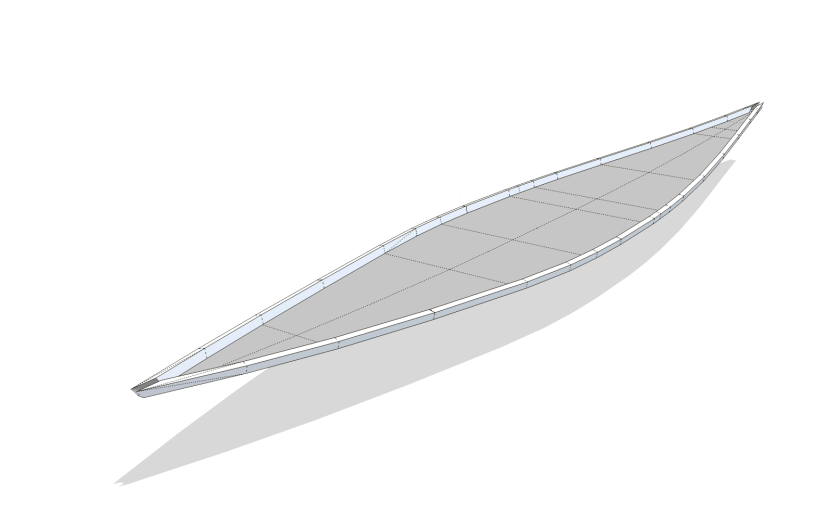

Upper Chine Logs

The deck chine-logs are installed next. Recheck that the frame is still level side-to-side, and that there is no twist. Note that a rolling bevel will be required in the forward portion of the chines. Consult with the building instructions for details.

Attaching the Sides

Oversized side panels are attached to the frame using construction adhesive and screws. Refer to the measured drawings for rough shape. They will be trimmed to shape in the next step.

Trimming the Sides

The boat is starting to take shape. Trim the side panels using the chine-logs as your guide. You now have the final shape of the sides and bottom.

Attaching the Deck Panel

This is a tricky bit; the deck panel is trimmed to rough dimensions in advance in order to take the complex curves which make the 24 Hour Kayak an unusually attractive 4 panel boat. Please note that the panel will overlap along the centre line, aft of the cockpit. This is by design; you will need to trim the overlaps to meet in a clean joint along the centre line.

Remember, don’t glue the deck panel to the temporary frames!

Laminating the Coaming and Trimming Deck Panel and Cockpit Opening

The coaming is laminated directly to the deck panel. Once the glue has dried the deck panel and cockpit opening are trimmed to final size.

Removing the Temporary Frames

Once all the panels are trimmed and the glue is set, the two centre frames are removed and the builder can start to contemplate fittings and finish. You will need a skeg in the rear but beyond that, what you add is up to you!

And That’s That

Remember, this page is a reference for advance builders and students; it’s all part of the development process; we want to make sure that everything is in place before we let the boat loose into the world. But we get it too, it’s all kind of a tease, isn’t it.

If this page has whet your appetite and you’d like to know when the plans are officially released subscribe to Ashes Newsletter, or our Facebook page, where the announcements will be made.

Many thanks,

Trevor Paetkau

Designer and Builder

Ashes Still Water Boats

Sao Paulo, Brasil

![]()

SUBSCRIBE

0 Response to "Build Sequence - The 24 Hour Kayak"

Post a Comment